Railroad Design and Construction Project – Idaho

Here is one of our most essential crew members doing a quick track inspection tour along one of our ongoing railroad construction projects.

What is a railroad design / railroad construction project?

Any design / build project begins with a need. Spur lines are essential to the American industrial system, and acts as the major thoroughfares between the largest railways of America, the Union Pacific Railroad (UPRR) and the Burlington Northern and Santa Fe Railway (BNSF). These spur lines act as the roots that connect all major plants, mines, lumber mills, and more to the stem of each major railway. By conducting a new railroad construction project, our job as a railroad contractor is to ensure that a new source of our industrial backbone is added to the network of trading and transportation for our country. When seeing it through this end, one can truly tell how essential spur line contractors are not only to the infrastructure of this country, but also its raw-goods economy.

How does the railroad design process begin?

So, now that we have covered its importance in our systems, now we can get down to how a track is really analyzed to discover the most efficient way to connect it to the UPRR or the BNSF. All designs require one of our track inspection teams to go on site and look at any existing site materials and rail lines. The crews look for flaws or potential hazards in the previous track, while making notes for future reference as new rail and ties are hauled in.

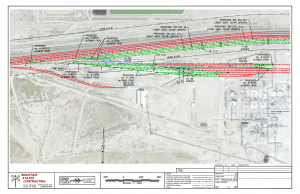

Also, while on the site, the supervisor will begin taking either aerial-drone shots of the site to map out the topography for the railroad design. This equipment allows us to measure relative distances, differences in grades, and any other relative geographical obstacles that may hinder the railroad construction project. The supervisor will also be responsible for looking into the surrounding area for any other buildings or previous constructions that may be hindered or obstructed by the introduction of the new spur line. These obstacles can include, but are not limited to: roads, rails, lines or pipes, buildings, etc.

One of our aerial measurement tools in action.

After this process, the data is sent back to our main office where our track architects begin the process of drafting and finalizing the final track lines to encompass the needs of our client, and the hazards of the site itself.

Thank you for joining us on this quick blog post, we are hoping to release more to not only share information on our practice, but also to support and encourage our community. Be sure to stay tuned.

Leave A Comment